Tips for getting the most out of your wood veneer for your project

On its face, ordering Wood Veneer Sheets or Custom Plywood is pretty straightforward. But there are a few, not-so-obvious things to consider that, in the long run, will often save you time and money. Especially, these five:

Order 10% More than You Think You Need

Honestly, ordering the exact amount of veneer your project specs call for really isn’t the best plan. To be safe and smart, you need to allow for contingencies — mistakes, mishaps, or miscalculations when applying your Wood Veneer Sheets or installing your Custom Plywood.

Rule of Thumb: It’s always best to have little more (we advise +10%) than you think you need, rather than winding up with a little less than the job requires. Mainly because you want to finish the job, appropriately, professionally, and timely.

Rule of Thumb: It’s always best to have little more (we advise +10%) than you think you need, rather than winding up with a little less than the job requires. Mainly because you want to finish the job, appropriately, professionally, and timely.

But it’s just as important to order more than enough material because if you do fall short, for whatever reason, it’s much more challenging to go back and reorder more veneer with the identical color and grain as your initial order — even at GL Veneer. Sure, your follow up order might be close to the first veneer you purchased, but the reality is no two trees are the same, and no two match exactly. So, it’s wisest to buy every square inch you think you’ll need – plus 10% – to make sure you’ve got the job covered in the most precisely matched wood material possible.

Use Higher-Grade Veneer in the Most Visible Areas

Part of the versatility and Benefits of Using Wood Veneer is that it allows you to apply different types of veneer to each side of your Custom Plywood or other workable surfaces in your design. And by different, we mean totally different — totally different wood species, totally different grades, totally different colors, even totally different materials.

This level of design control allows you to laminate your “hero” surfaces (what we call the “face” of Custom Plywood) – those with the highest visibility in the final design – with premium grade wood veneer, and the less or “non-visible” surfaces (the “back” of Custom Plywood) with a lesser grade, lesser quality, and less costly material.

For example, say you want to install beautiful, English Brown Oak custom cabinets in your kitchen. Awesome. A beautiful, dark, wood veneer — that sells for roughly $228 to $367 a sheet. But nothing says you have to laminate both sides of your Custom Plywood with English Brown Oak. So don’t.

Instead, laminate the “hero” face that everyone will see – the outside doors of your cabinets – with English Brown Oak. But then use the less expensive, lighter colored Plain Sliced Red Oak on the backs of your cabinet door panels — for just $23 to $66 dollars per sheet. Then to make every surface inside your cabinets matches, including the shelves, laminate those panels with the same Plain Sliced Red Oak on both sides, face and back, for a totally pleasing lighter interior throughout. Everyone will rave when they see your beautiful new kitchen cabinets and see their great looking interiors — if they ever actually look inside them.

Instead, laminate the “hero” face that everyone will see – the outside doors of your cabinets – with English Brown Oak. But then use the less expensive, lighter colored Plain Sliced Red Oak on the backs of your cabinet door panels — for just $23 to $66 dollars per sheet. Then to make every surface inside your cabinets matches, including the shelves, laminate those panels with the same Plain Sliced Red Oak on both sides, face and back, for a totally pleasing lighter interior throughout. Everyone will rave when they see your beautiful new kitchen cabinets and see their great looking interiors — if they ever actually look inside them.

Effectively, you’ll get more bang for your buck, investing more of your budget in the parts of your project those dollars can be appreciated and not spending money needlessly where no one will ever notice.

Same goes for wall panels. Laminate your “hero” face side with whatever veneer you love most. And the back – which will be installed against the wall, never to be seen again – with a super affordable, Grade 3 “mill option” backer. Out of sight, out of mind, NOT out of money.

This level of planning and control is yet another reason why designers, architects, artisans, and other woodworking professionals love using flexible Wood Veneer Sheets. And is the basis for the famous interior design saying: “Put your money where you’ll see it.”

Choose Sequence Matched Veneers

The final look of your project can either flow naturally and seamlessly or haphazardly and disjointedly in a distracting manner. Clearly you want the former. What creates a nice natural flow is “veneer matching,” which refers to the way the “flitches” (or “leaves”) of wood veneer are matched and spliced together.

While there are several standard ways to match Wood Veneer Sheets and Custom Plywood panels, most veneers are “Book Matched” or “Slip Matched.”

When every other leaf of veneer is turned over – or “opened like the pages of a book” – that sequencing technique is called “Book Matching.” When the leaves of veneer are “slipped” or laid side by side – without turning every other one over – the technique is referred to as “Slip Matching.”

When following methodical, consistent sequencing to create veneer faces, the natural growth patterns of the tree will cause the figure on the sequential panels to ascend, descend, or show a “grain progression” as the eye moves from panel to panel. The patterns can be subtle or obvious, but when they’re sequence matched artfully the perceived “patterns” they create will flow in more visually pleasing ways.

For this reason, Custom Plywood used in furniture or Wood Veneer Paneling applied in the same area of your design should match, no matter what sequencing you choose. And if your wood veneer project calls for large design areas requiring the most uniform look possible, try using a wood species that produces large consistent sequences, including these great examples:

- Plain Sliced Walnut

- Plain Sliced White Oak

- Quarter Cut Sapele

- Quarter Cut Eucalyptus

Understand the Wood Veneer Terms

If you’re new to wood veneer, or it’s been a while since you worked on a wood veneer project, it’s essential you familiarize yourself with “veneer terminology” before you start choosing and purchasing your material. Not only do you want to understand what you’ll be buying, you’re going to want to know how to describe what you’re looking for when talking with a supplier. Just makes things a lot easier. And you’ll feel a lot more confident.

Terms like “Birdseye,” “Curl,” “Mottle,” and “Figure” are examples of ways we describe the patterns found in the grain of some trees. At the same time, there a variety of terms used to describe how the wood is cut, which will often affect its appearance and texture. Combining several descriptive terms like these will often be used to describe the distinctive arrangements of the wood grain that make each piece one-of-a-kind. Some naming/terminology examples include:

- Quarter Cut Flaky Red Oak

- Rotary Spliced Quilted Cherry

- Bubinga Pommele

- Premium Vertical Grain Douglas-Fir

- Rustic Swirl Carpathian Elm

- Plain Sliced Heavy Figured Claro Walnut

Learning these industry terms, and more like them, will make your ordering process much easier and effective. Actually, understanding wood veneer terminology like “Sequence Matching,” “Quarter Cut,” “MDF,” and “Wood Backers” will be just as helpful in the early, planning stages of your project as well.

For a really great reference, check out the wood veneer terminology page on the wiseWood veneer website.

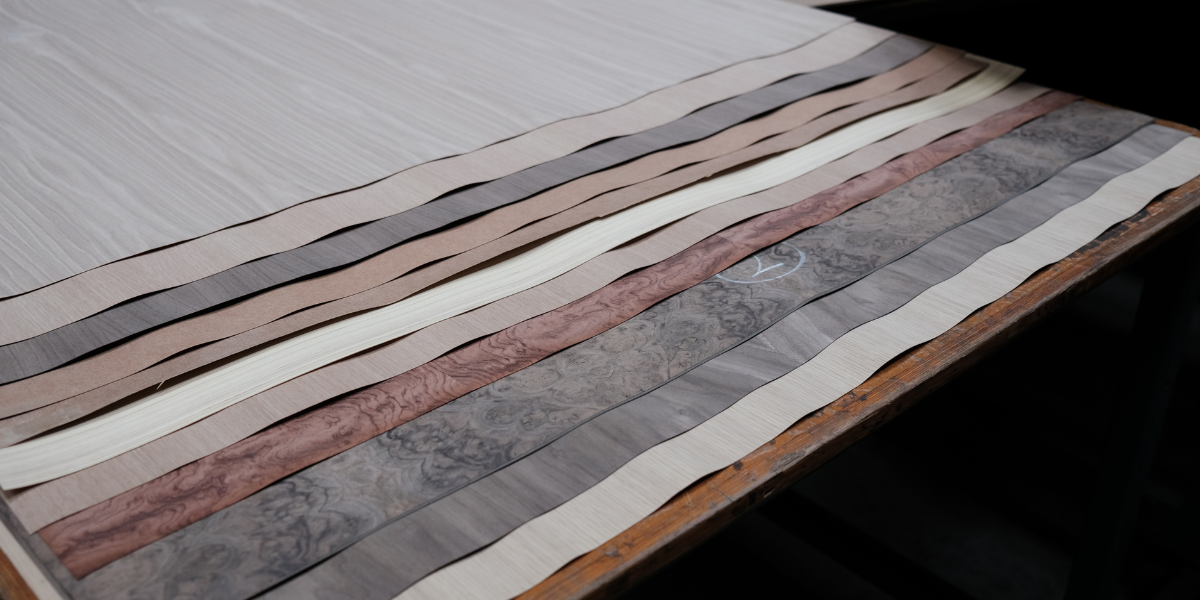

Hand Select Your Veneer Sheets

Whenever possible, handpick your wood veneer sheets yourself. On site. In person. Doing so allows you to make executive design decisions about each sheet on the fly. And let’s you ensure the sheets you like will provide the exact type of sequencing you’re looking for.

The most beautiful part of natural wood is that it’s natural. Not fabricated. Hardly uniform. And anything but predictable. That’s why we love it and all it’s variations in color, texture, and figure – both subtle and dramatic – often within the same species, at times even within in the same tree.

So the honest truth is, if you can’t handpick your material, you can’t expect the veneer you order online to look exactly like the sample picture you reference. It’ll be close, for sure. But exact? — that’s not natural.

Again, the only way to guarantee the precise look you want is by visiting the supplier’s warehouse and flipping through the veneer sheets to select the exact ones you want for your project. It’s not only what we encourage at GL Veneer, it’s what we do — every single day.

Customers come to our 150,000 square foot warehouse every day, from all over, to hand select their veneer. And you’re just as invited as they are. Give us a call, or just stop by anytime. We’ll meet you, greet you, and help you every step of the way.

It’s what we do. And why we’re called: “The Home of the Wood.”